Description

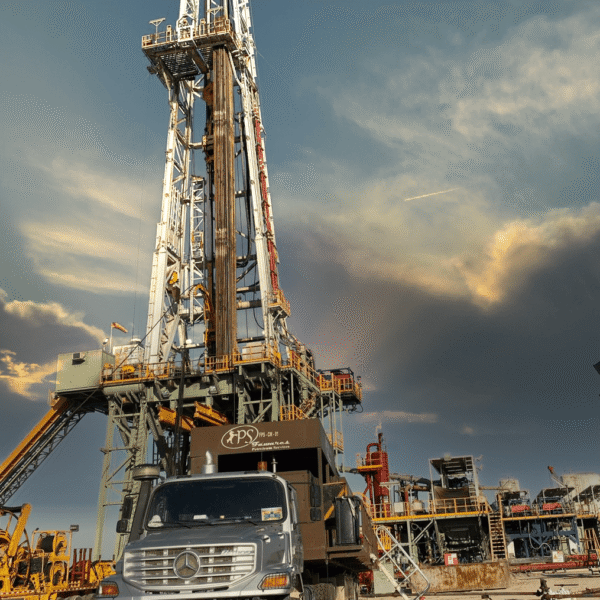

Oil-well cementing is pumping cement slurry down the annulus in mind of the casing & wellbore. This is known as the primary cementing process. The main function is to form a cement sheath that will ensure zonal isolation, support, and shield of the casing. For this purpose, you need exceptional oilfield & cementing services.

Also, these services are used to develop and pump cement into a wellbore. Cementing assists in protecting and sealing a wellbore. Using a cementing process to fill the void in the center of the casing and the borehole has three essential functions.

Supports the casing, shields it from corrosion, and isolates the well’s oil-gas-water-producing zones. However, it Prevents blowouts by forming a seal.

Cement Transport, Handling & Storage Equipment

Dry cement is transported from one place to another or from the supplier or Service Company yard to the oil & gas company. Also, directly to the well-site by road, rail. The cement is stored in bulk silos, big bags & sacks.Bulk silos come in different sizes and shapes, depending on whether part of a stationary installation or a mobile unit is available for space. The standard size is 38 m3 (1350 cubic feet), also frequently utilized for other bulk commodities such as bentonite & barite. The silos are fixed with nozzles for blowing air to ‘fluidize’ the dry material and a few arrangements to gauge the contents.

Cementing Mixing & Pumping Equipment

The second cementing service used for the preparation of a slurry is done by blending the cement with the mixed water exerting enough shear to disperse particles and encourage accurate yielding into a homogeneous mass system.

The slurry made in the cementing unit is typically pumped to the casing head via a temporary connection. The connection to the cementing unit is made via a short length of high-pressure hose or made up of Chickasaw joints.Secondary or remedial cementing is usually carried out via drill pipe and cementing stringer. In this scenario, the slurry is delivered to the standpipe manifold & CT unit via a temporary link or a dedicated delivery line.

Cementing Units

Cementing unit Equipment or cementing services are developed for pumping cement into the well. They are utilized for drilling, workover, and killing well functions.

The main components of the cementing unit or cementing services are:

- ✓ Storage Bulk Tanks

- ✓ Liquid additive storage and mixing

- ✓ Cement Pump

- ✓ Surge tanks

- ✓ Cement Mixer